Q&A with KF Flight Instructor Jyothi Bachwala

On discovering work-life balance and passion in military aircrew training As a Class 2 Phase 1 Flight Instructor [...]

KF Aerospace to support the P-8A – Canada’s new Multi-Mission Aircraft

The Boeing P-8 is truly a multi-mission maritime patrol aircraft, excelling at anti-submarine warfare; anti-surface warfare; intelligence, surveillance and reconnaissance [...]

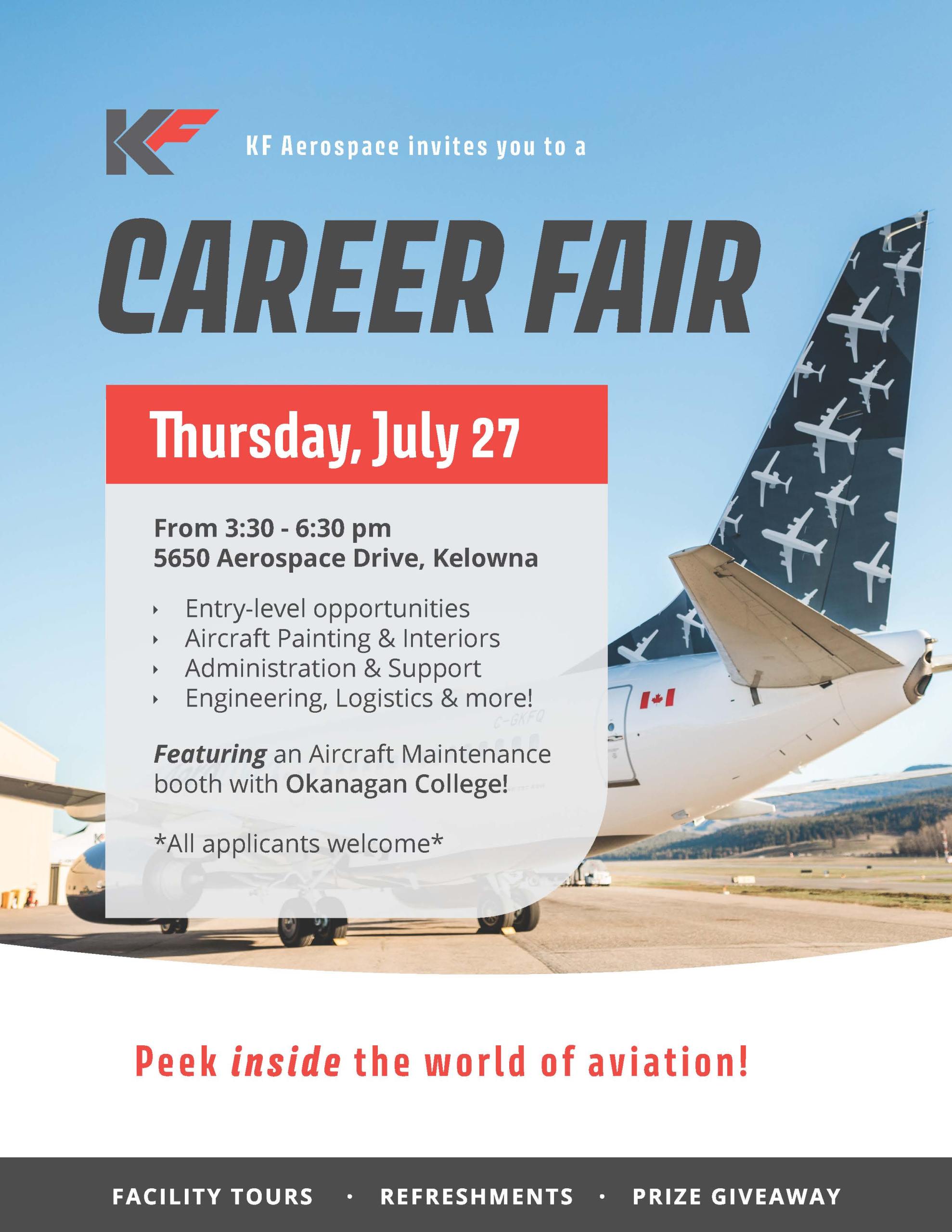

You’re invited to the KF Aerospace Career Fair!

EVENT DETAILS DATE: Thursday, July 27 TIME: From 3:30 to 6:30pm LOCATION: 5650 [...]

Women of Aviation Week with KF Aerospace

From aircraft maintenance to military pilot training—our team members play a vital role in Canada’s exciting aviation industry. In [...]

A holiday wish list for Canada’s aerospace sector

An opinion piece published in the Hill Times | November 28, 2022 By Grant Stevens, Chief Corporate Services Officer at [...]

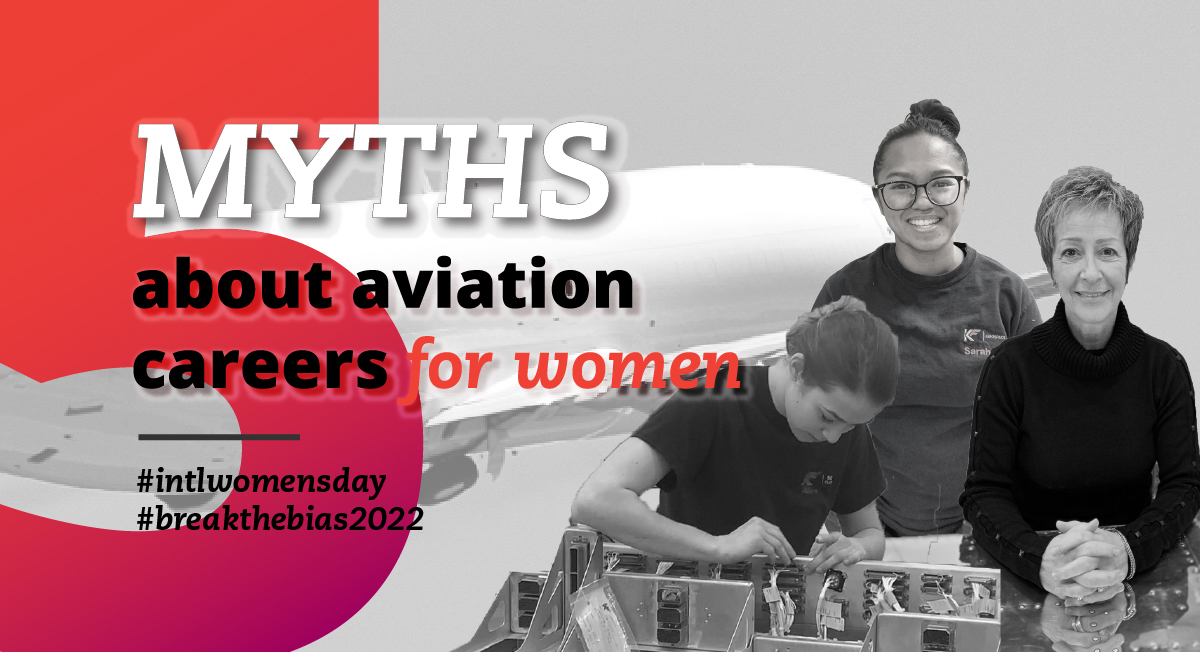

Aviation Careers for Women | 5 Myths

Myth #1: Mechanical skill is something you're born with. “I wasn’t planning on a career in aviation, I [...]

KF and the CC-115 Buffalo: A Farewell Story

Last weekend the venerable CC-115 Buffalo flew its final mission (news story here). From international peacekeeping to critical life-saving missions [...]

Why and How KF is Restoring a Warplane

Nearly 80 years after missing its role in the theatre of war, the Hawker Tempest II will take centre [...]

Heavy Lifting (pt. 2): Conversion Complete!

What does it take to transition a passenger aircraft into the big business of air cargo? In Part 2 [...]

5 Questions with Structures AME | Renee Mason

1. What inspired you to pursue a career in aviation? "I had just finished the carpentry-joinery program but wasn’t [...]

5 Questions with Connie Stephany | Structures Composites Technician

1. What is your earliest memory or experience of aviation? My grandfather was a bomber pilot in WW2 for [...]

Into the Craft with Dennis Mikuletic and Ryan Defty

Repair Shop Component Technicians, Dennis Mikuletic and Ryan Defty tell us about the finer points of landing gear overhaul, [...]