Shop capabilities are critical to our success

KF completes the majority of work on-site, allowing for reduced risks and costs of outsourcing, and better support of customer visits. KF manufactures CV parts, B727 and B737 -200 parts, along with AOG capabilities in conjunction with Boeing-Douglas.

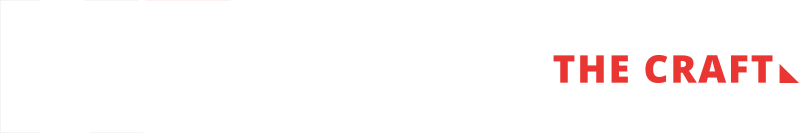

- Phased Array Ultrasonic (PA)

- Liquid Penetrant (LPI)

- Magnetic Particle Inspection (MT)

- Ultrasonic (UT)

- Eddy Current (ET)

- Radiography (RT)

- X-ray fluorescence (XRF/PMI) and Positive Material Identification

- Visual

Both KF facilities have fully certified NDT staff on-site, including up to Level 3 Certifications. Our Level 3 NDT services are used in the development of techniques for engineering and training.

Certifications: RT-3, PT-3, ET-3, UT-3, MT-2, EDO, XRF-2, NAS 410 level 3, RT, UT, ET, PT and MT.

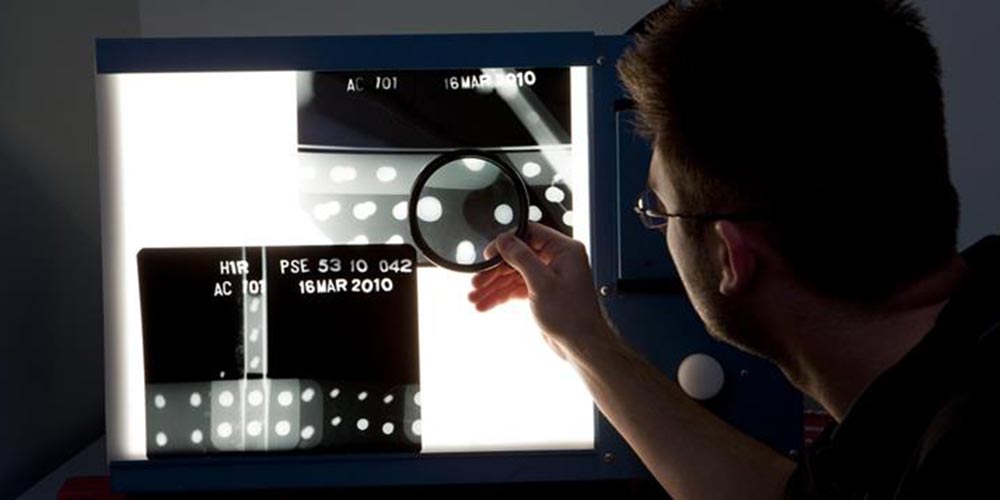

Our components shop performs repairs and overhauls on various types of components and landing gear for a variety of aircraft types, including Boeing 727 and 737’s, Boeing-Douglas, Convair, and De Havilland Buffalo and Twin Otter.

Our components shop performs repairs and overhauls on various types of components and landing gear for a variety of aircraft types, including Boeing 727 and 737’s, Boeing-Douglas, Convair, and De Havilland Buffalo and Twin Otter.

The repair processes that require plating, machining, NDT, painting, and shot peening are all completed onsite in our facility.

Please see below a sample of our Component Shop’s capabilities:

- Wheel Assemblies and Components

- Brake Assemblies and Components

- Actuators:

- Krueger Flap Actuators, Ground Spoiler Actuators, Slat Actuators

- Flap Position Transmitters

- Engine Mounts and Housings

- I/B and O/B Flap Carriages

- I/B and O/B Flap Tracks

- Air stair Assemblies and Components

- Gearboxes:

- Aileron Lockout Gearboxes, Flap Drive Gearboxes

- Cargo Handling System Components

- Cargo Door Components:

- Selector Valves, Relief Valves

- Torque Tubes

- Tube Assemblies

- Webber and Castle Seat Assemblies and Components

- Coffee Makers and Ovens.

- Engine Bleed Valves

- Fuel Filters

- Lavatory Check Valves

- Hydraulic Actuators:

- Landing Gear Actuators, Rudder Actuators, Steering Actuators, Spoiler Actuators

- Hydraulic Tanks

- Hydraulic Tubes

- Hydraulic Filters

- Wheel Assemblies and Components

- Brake Assemblies and Components

- Valves:

- Anti-Skid Solenoid Valves, Check Valves, Depressurization Valves, Drain Valves, Emergency Latch Valves, Flow Regulator Valves, Fuel Vent Valves, Hydraulic Relief Valve, Metering Check Valves, Nose Steering Actuator Valves, NLG Relief Valves, Power Brake Valves, Relief Valves, Restrictor Valves, Snubber Valves

- Hydraulic Accumulators

- Propeller Brush Block Assemblies

- Actuators:

- Air stair Actuators, Nacelle Vent Actuators, Nose Steering Actuators, Main Entrance Door Actuators, Oil Cooler Door Actuators

- Gearboxes

- Torque Tubes

- Lord Mounts and Housings

- Filters:

- High-Pressure Fuel Filters, Power Section Oil Filters, Prop Filters, Reduction Gearbox Oil Filters, Speed Sense Filters

- Hydraulic Components

- Microswitches

- Tube Assemblies

- Allison Engine Anti-Ice Shrouds

- Windshield Wiper Components:

- Speed Control Valves, Wiper Actuating Units, Wiper Control Units

- Window Frames

- Fuel Manifolds

- GTC Alternator Drives

- Cargo Door Components

Our Machine Shop supports the repair processes for our internal shops including the Landing Gear Shop. This includes grinding both inner and outer surfaces of shock strut components.

Our Machine Shop supports the repair processes for our internal shops including the Landing Gear Shop. This includes grinding both inner and outer surfaces of shock strut components.

Our Machine Shop also performs the OEM (Original Equipment Manufacturing) machining requirements for our Manufacturing Department in support of our Convair fleet and worldwide customers.

The Machine Shop has specialized equipment including CNC machines, grinders and boring mills:

- Rotary table

- X – 40”

- Y – 20”

- Z – 20”

- 7500 RPM spindle

- Up to 4 axis, full 4th axis capabilities

- 90-degree spindle

- Full CNC with live tooling

- Mill-turn capability

- 14” diameter turning capacity

- 10” chuck

- 18” length between centers

- Strut grinder

- 80″ swing at the gap

- 72″ length

- 5500lb capacity

- 24” spindle travel

- X – 70”

- Y – 30”

- Z – 47”

- Rotary table

- Used for repairing landing gear

- Two machines available for increased production

- 10” diameter

- 28” long

- Sink EDM

- 18” by 33” capacity

Our full-service plating shop performs shot peening, cleaning, etching and chroming.

We use the latest plating technologies including, hard chrome, dull and bright cadmium, alodine and nickel, complete with all the necessary etching and sealing.

Our Plating Shop’s capabilities include the following:

- SAE AMS-QQ-P-416

- SOPM 20-42-01

- MIL-STD-865D

- SOPM 20-42-05

- SOPM 20-42-03

- AMS 2460-Class 2

- MIL-DTL-5541F

- BAC5625

- BAC5771

- MIL-S-5002D

- MIL-STD-871B

- SOPM 20-42-09

- SOPM 20-10-03

- AMS 2430

The Structures Shop supports our MRO customers and Manufacturing. It is not uncommon for flight controls, thrust reversers, passenger/cargo doors and other components to be removed and routed through the shop for repairs. Our Structures Shop also supports spare component repairs for a variety of customers operating Convair 580’s and 5800’s, Boeing 727’s, Boeing 737 Classics and NG’s, and De Havilland Buffalo and Twin Otters.

The Structures Shop supports our MRO customers and Manufacturing. It is not uncommon for flight controls, thrust reversers, passenger/cargo doors and other components to be removed and routed through the shop for repairs. Our Structures Shop also supports spare component repairs for a variety of customers operating Convair 580’s and 5800’s, Boeing 727’s, Boeing 737 Classics and NG’s, and De Havilland Buffalo and Twin Otters.

Our Structures Shop is also capable of welding, in accordance with AWS D17.1 TIG, the following materials – aluminum, stainless steel, titanium and steel. We have welded a variety of component parts: engine mounts, ducts, assemblies including tooling and the manufacture of parts.

We are also able to form aluminum, steel and stainless steel parts – forming with rubber press, brake, shear and other specialized tooling.

The Interior Shops are integrated with hangar operations, allowing customers direct access to experts in cleaning, inspection and repair of:

The Interior Shops are integrated with hangar operations, allowing customers direct access to experts in cleaning, inspection and repair of:

- Seats

- Galleys

- Lavatories

- PSU’s

- Overhead Bins

- Flooring (Carpet, Coin dot, etc)

- Internal Panels

Our paint shop is capable of painting everything from individual parts up to narrow-body aircraft. Using state-of-the-art facilities and techniques, KF completes over 25 full aircraft paint jobs annually as part of a maintenance check.

Our paint shop is capable of painting everything from individual parts up to narrow-body aircraft. Using state-of-the-art facilities and techniques, KF completes over 25 full aircraft paint jobs annually as part of a maintenance check.

KF utilizes three downdraft paint booths for part and component painting, and designated hangar facilities for aircraft painting.

Composite Shop has the capability and proficiency to conduct:

Composite Shop has the capability and proficiency to conduct:

- Wet Lay-up Repairs

- Elevated Temperature Wet Lay-up

- 250 and 350 Degree Prepreg Hot-Bond Repairs

- Fibreglass, Graphite, Aramid and Hybrid Structures

- Sandwich Panel with Nomex or Phenolic Honeycomb

- Bonded Metal Hot-Bond

- Pre-Bond Surface Treatment

- Metal Sandwich Panel

Our Upholstery Shop manufactures and repairs the following:

Our Upholstery Shop manufactures and repairs the following:

- Seat covers and cushions

- Curtains and drapes

- Map and document pouches

- Anti-Ice blankets

- Carpet binding

- Products that meet Flammability Requirements of FAR 25.853

Our Heat Treating capabilities include the following:

Our Heat Treating capabilities include the following:

- Aluminum solution heat treatment and artificial aging (AMS 2770)

- Meeting all Pyrometry requirements (AMS2750, BAC 5621)

- Stress relieving and Precipitation harden (AMS 2759/3)

- Controlled composite cure cycle capabilities

Our application processes include:

- Tempering

- Solution Treating

- Aging

- Annealing

- Normalizing

- Stress Relieving

Our heat treating equipment includes:

- Interior size 36″x36″x48″

- Re-circulating air furnace

- Temperature controls capable of maintaining a uniform temperature

- Max temperature 500°F

- Certified to AMS2750

- Interior size 24″x24″x24″

- Re-circulating air furnace

- Temperature controls capable of maintaining a uniform temperature

- Max temperature 850°F

- Certified to AMS2750

- Interior size 76″x71″x83″

- Re-circulating air furnace with temperature controls capable of maintaining a uniform temperature

- Certified to AMS2750

- Interior size 30″x30″x48″

- Max Temperature 1250°F

- Re-circulating air furnace

- temperature controls capable of maintaining a uniform temperature

- Water quench tank with circulation and temperature recording device

- Certified to AMS2750

Our full-service avionics shop is able to repair, overhaul and modify equipment from some of the world’s top manufacturers. Our facility also has a wire harness fabrication shop capable of single runs to full harness fabrication with laser stamping all done in-house.

Our full-service avionics shop is able to repair, overhaul and modify equipment from some of the world’s top manufacturers. Our facility also has a wire harness fabrication shop capable of single runs to full harness fabrication with laser stamping all done in-house.

- Wire Harness Fabrication Shop

- RadioShop

- Avionics Modification Upgrade Kits

- Laser Wire Marking

A full complement of qualified staff, with the right tools, and a bright spacious shop to meet your needs.

- Electrical systems

- Auto flight control systems

- Flight director systems

- Navigation systems

- Communication systems

- Flight management systems

- Instruments

- Laser stamping

- In house wire harness fabrication shop

- Avionics modification upgrade kits

- Trained Technicians

KF also repairs and maintains commercial and aviation radios. We have an extensive Avionics library and experienced staff.

We are a certified repair center for Bendix/King, Rockwell Collins and Honeywell.

Utilizing CAD drawings and two laser wire markers, KF staff can manufacture wire harnesses for installation at our facility or yours.

Utilizing CAD drawings and two laser wire markers, KF staff can manufacture wire harnesses for installation at our facility or yours.

Our staff has created wire harness kits for full avionic upgrades to aircrafts such as the Twin Otter, Buffalo, Bell 412, Convair 580/5800, Mi-17, and T-33.